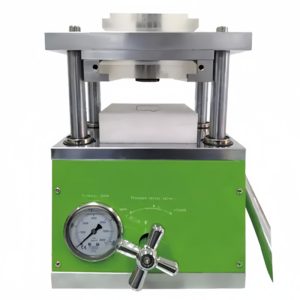

An Electric Electrode Calendering Machine with Horizontally-Aligned Rollers is a precision industrial machine used primarily in battery manufacturing (e.g., lithium-ion, solid-state batteries) to compress electrode coatings (anode/cathode slurries) onto current collectors (foils) to achieve uniform thickness, density, and smooth surface finish. The horizontal roller alignment distinguishes it from vertical designs, offering advantages in stability, accessibility, and process control.

Features

- Heating and rolling with a temperature controller that allows adjusting the temperature control and a digital display.

- Optional heating or non-heating operation.

- The rolls have high hardness, with a hardness of up to HRC62, and anti-rust properties.

- The pressing gap is adjusted with a wedge block, which features great self-locking and high adjustment precision.

- Roller rolling has high accuracy, with rolling cylindricity ≤ ±2µm.

- Horizontal design for convenient feeding and rolling of sheet and strip materials.

- Gear meshing is used for rotation, achieving opposed roller pressing.

- The thickness and speed of the electrode sheets are adjustable, with a compact and aesthetically pleasing design.

- Electric rolling for automation, with forward and reverse operation capabilities.

- Compact size, simple operation, flexible, and quick to use.

Specifications

| Product Name | Electric Electrode Calendering Machine Horizontally-aligned Rollers |

| Roller Diameter | Ø 96mm |

| Roller Hardness | Above HRC62 |

| Roller Roughness | Above 0.4 |

| Rolling Thickness | 0-2 mm |

| Rolling Width | 0~100 mm |

| Roller Install Method | Place horizontally |

| Rolling Temperature | 200℃ |

| Rolling Speed | 0-10 mm/s |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 720W |

| Product Dimension | 500mm*220mm*320mm(L*W*H) |

| Net Weight | 55KG |