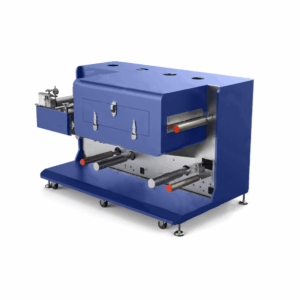

This Cutting-Folding-Thermal Forming Integrated Machine combines three critical processes in pouch cell production into one automated workstation, significantly improving production efficiency and quality consistency. This Cutting-Folding-Thermal Forming Integrated Machine consists of four mechanisms, namely the battery cell correction and positioning mechanism, the trimming mechanism, the folding mechanism, and the edge sealing mechanism. The operator manually feeds the material, and after the battery cell is corrected and positioned, presses the start button with both hands. The equipment starts to operate. The battery cell goes through trimming, folding, and edge sealing processes to be formed. Then, the battery cell fixture returns to the initial position.

Features

- Suitable for both single and double folding.

- The cutting blade rotates synchronously in the opposite direction, ensuring high cutting precision and a blade durability of over 1 million operations.

- Four major mechanisms can be adjusted in and out simultaneously, offering flexible and convenient adjustment.

- Capable of holding multiple products at the same time, ensuring high efficiency.

- Manual and automatic operation modes are available.

- Position adjustment of all mechanisms is guided by linear rails.

- The creasing wheel is made of die steel, ensuring durability and wear resistance.

- The speed of the cutting blade and clamps, as well as the edge heating temperature, are all adjustable.

Specifications

| Product Name | Cutting-Folding-Thermal Forming Integrated Machine |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 2. 5KW |

| Operating Efficiency | 160 – 220 times per hour |

| Input Air Pressure | 0.5Mpa-0.7Mpa |

| Cutting Blade Durability | 1 million times |

| Cutting Precision | ±0.1mm |

| Product Dimension | 350mm*750mm*1800mm(L*W*H) |

| Net Weight | 300KG |