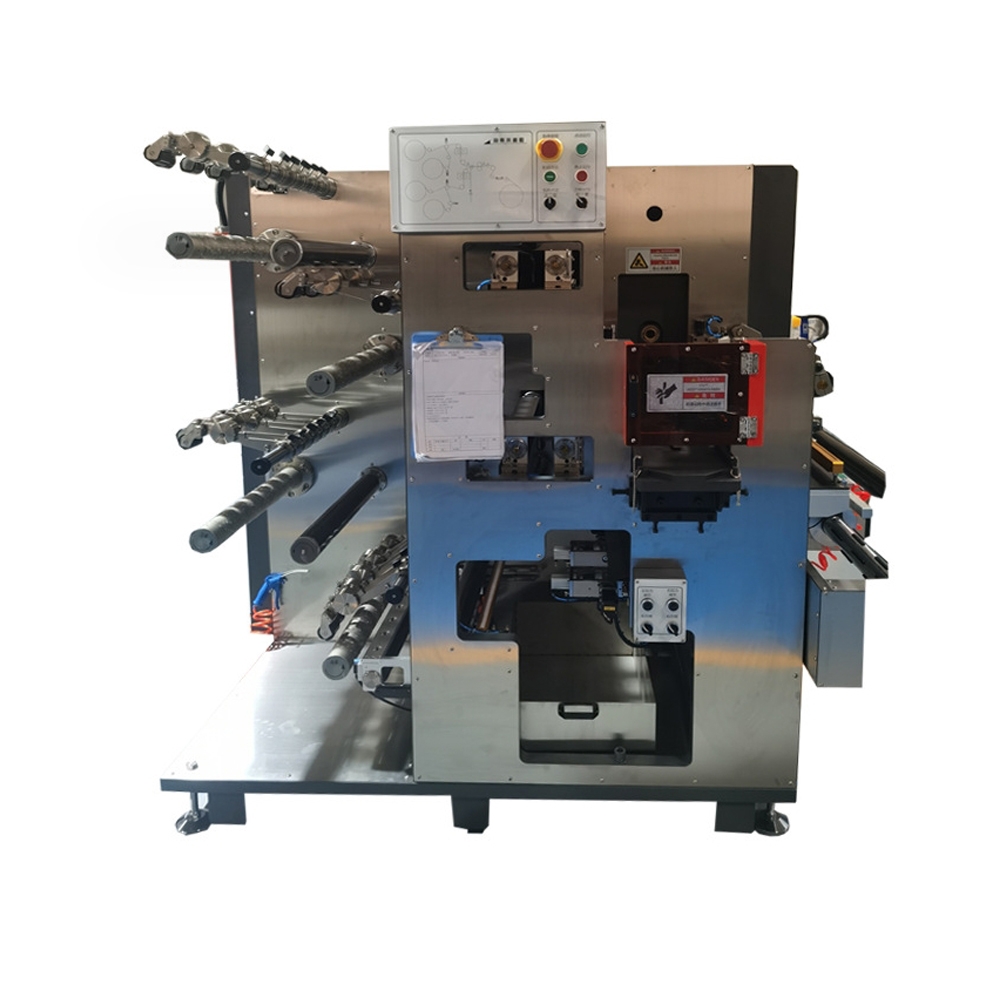

The Roll-to-Roll Continuous Electrode Slitting Machine adopts the continuous slitting process of two or more strips of electrode materials. The equipment is equipped with a precision tool holder, which can achieve extremely high-precision foil slitting and is widely used in the lithium battery, metal foil, optical film, and other functional film industries. This automated solution ensures burr-free edges, minimal material waste, and consistent strip widths critical for cell assembly.

Features

- Blade materials are Ultrafine Tungsten Alloy for better slitting quality and extended blade durability.

- High precision in slitting width, ensuring finished products are free of burrs, waves, or indentations.

- Adjustable cutting depth and cutting speed.

- By adjusting the feeding angles, it can adapt to slitting materials of different thicknesses and types.

- The machine is equipped with an independent blade holder and a De-dusting device.

- Upper and lower sets of high-precision round disc blades.

- Automatic control of reeling tension ≤ 50N.

- PLC control panel and HMI operation for convenient and user-friendly use.

Specifications

| Product Name | Roll-to-Roll Continuous Electrode Slitting Machine |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 1 KW |

| Slitting Method | Single-piece rotary cutting |

| Blade Type | The upper and lower sets of circular blades |

| Cutting Width Adjustment Method | Replace the spacer to adjust |

| Cutting Thickness | 100~300 μm |

| Cutting Blade | Ultrafine Tungsten Alloy, Ø 100 mm |

| Cutting Width | 20 ~ 230 mm (20 ~ 280 mm could be customized) |

| Burr Condition | ≤ 25μm |

| Cutting Depth | 0.2 ~ 0.4 mm, with dial gauge display. |

| Cutting Speed | Max 4m/min |

| Net Weight | 100 KG |