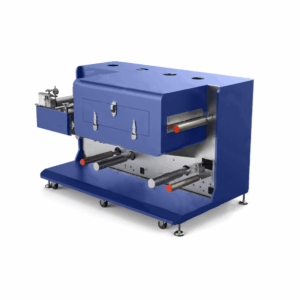

A spot welder for cylindrical lithium-ion battery cells is a precision welding machine designed to attach the bottom current collector tab (typically nickel or aluminum) to the cell can (steel or aluminum). This ensures strong electrical contact and mechanical stability for battery performance and safety. This Spot Welder for Welding Bottom Tab of Cylinder Cells is a widely adopted AC pulse spot welding machine, designed for welding the negative terminal (bottom shell) to the tab of cylindrical battery cells using single-pin welding.

Features

- The welding current is precisely controlled, ensuring uniform and aesthetically pleasing weld spots with minimal sparks and no discoloration.

- It fully overcomes the issues of low voltage and water leakage commonly encountered after lithium battery spot welding, making it an ideal equipment for battery production and assembly.

- Equipped with a microcomputer single-chip control system, it can achieve single-pulse, double-pulse, and multi-pulse welding.

- All parameters are set digitally, ensuring intuitive and accurate parameter adjustment.

- The pressure of the two welding needles can be independently adjusted, and the adjustment is convenient, ensuring stable and reliable welding pressure.

- Precise alignment for welding, suitable for welding small-cap battery cells, with a high success rate.

- Compact, lightweight, and elegantly designed.

Specifications

| Product Name | Spot Welder for Welding Bottom Tab of Cylinder Cells |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Output Maximum Power | 10 KVA |

| Welding Current | 0~99 A |

| Input Air Pressure | 0.3-0.7 MPa |

| Welding Thickness | 0.03 mm ~ 0.25 mm |

| Net Weight | 45 Kg |

| Product Dimension | 500*300*470mm (L*W*H) |