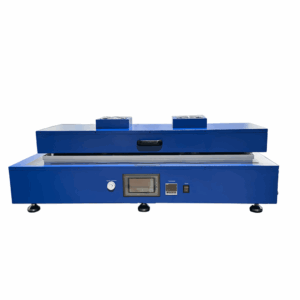

The Electrolyte Diffusion & Degassing Chamber facilitates the uniform diffusion of electrolyte and the removal of internal gas under vacuum conditions, ensuring better wetting, reduced gas formation, and improved battery cell stability. Ideal for use after electrolyte injection and before final sealing in lithium battery production lines. The whole machine is made of high-quality electrical components and materials, suitable for various specifications and sizes of batteries. It features simple operation and high production efficiency.

Features

- It is capable of accommodating batteries of different specifications, with simple and convenient adjustment.

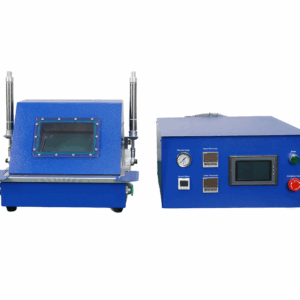

- Features a host and a control box in a split design, allowing the machine to be placed inside a glove box or on a production line for operation.

- Maintains stable vacuum levels with minimal drop during the working process.

- Equipped with multi-stage cyclic operation functions, which help achieve more thorough electrolyte fusion.

- Provides a viewing window to observe changes inside the chamber during operation.

- The upper chamber is driven by a cylinder and guided by two linear guides, ensuring flexible and precise vertical movement to meet product sealing requirements.

- Simple to operate, compact in size, and lightweight.

Specifications

| Product Nane | Electrolyte Diffusion & Degassing Chamber for Lithium Cells |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 100 W |

| Required Working Pressure | 0.5–0.8 MPa |

| Inside Chamber volume | 320*220*175mm (L*W*H) |

| Size of the Working Part | 500*350*630mm (L*W*H) |

| Size of the Control Part | 460*350*340mm (L*W*H) |

| Net Weight | About 50 Kg |

| Chamber Material | Made of aluminum alloy, corrosion-resistant, and with a solid structure. |

| Rest Time | 0 ~ 99.99 seconds, adjustable |

| Vacuum Range | -95 ~ 0 KPa |