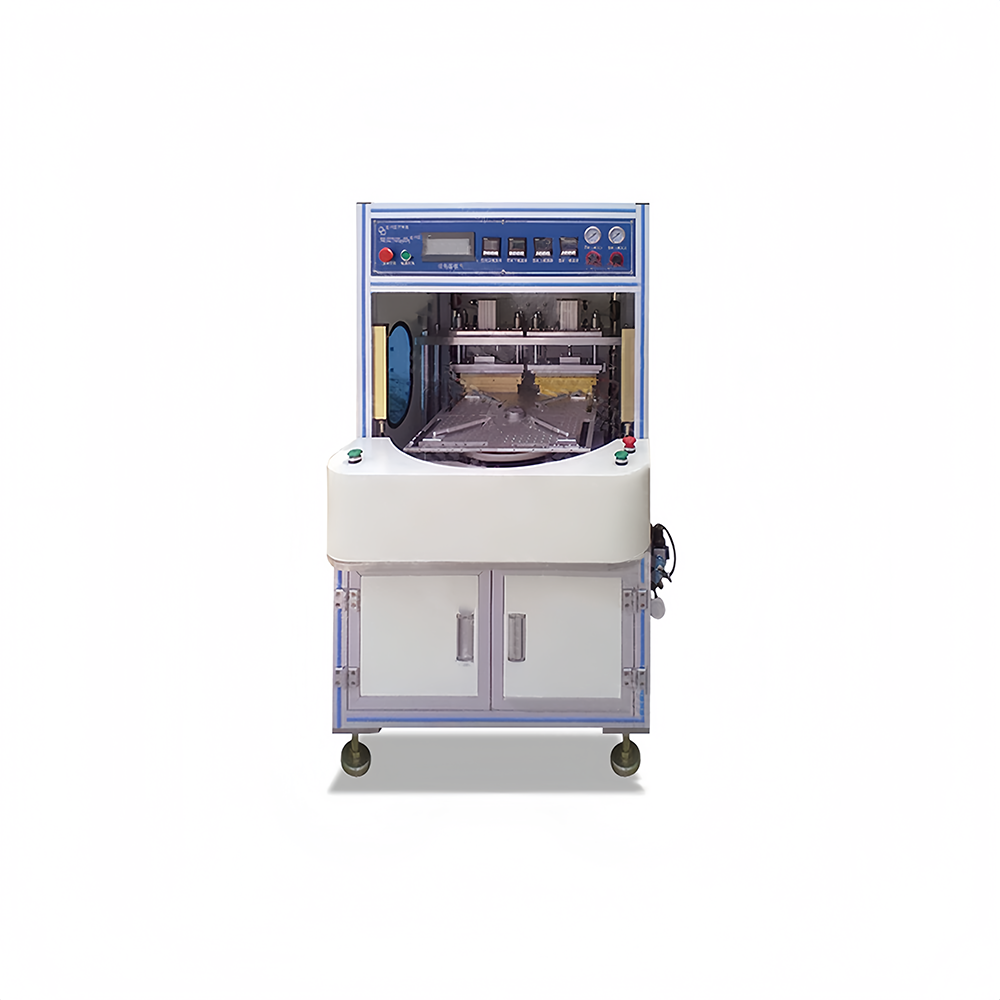

The Automatic Quad Station Heat Sealing Machine for Pouch Cells is an advanced heat sealing solution designed. Featuring four independent sealing stations, this automated system enables high-speed, high-precision thermal sealing of aluminum-laminated film (also known as Al-plastic film) enclosures. An Automatic Quad Station Heat Sealing Machine is ideal for medium to large-scale battery production lines, ensuring uniform sealing strength and superior air-tightness to enhance cell reliability and safety. This Advanced Quad-Station Seal Machine for Lithium Batteries is easy to operate, highly efficient, and has stable precision and good consistency. It is convenient to change models and can be used in both hard-sealing and soft-sealing processes.

Features

- Quad-Station Synchronized Operation: Features four workstations (Top Seal, Side Seal, Unloading, and Loading) for simultaneous processing of two batteries, significantly boosting throughput with minimal manual intervention.

- Precision Control: Achieves ±0.01mm parallelism and ±2℃ temperature control (adjustable up to 250℃), ensuring consistent sealing quality. Customizable seal width (2-8mm) and adjustable pressure (0-0.6MPa) for versatile application requirements.

- Automation & Intelligence: Integrates PLC control and a user-friendly touchscreen interface for seamless operation. Equipped with sensors to detect batteries, activating the sealing only when present, reducing errors.

- Flexibility & Compact Design: Adapts to various battery sizes (e.g., 10×420×20mm) with adjustable fixtures. Compact dimensions (870×870×1500mm) and lightweight (300-450kg) for easy mobility and integration.

- Safety & Reliability:Equipped with safety doors and dual-button start protection to prevent accidental operation. Constructed with brass sealing heads for efficient heat transfer and easy replacement of soft/hard seals.

- Mold Stroke: Adjustable upper and lower mold stroke.

- Sealing Head Parallelism: The sealing head parallelism is controlled within ±0.01 mm, as verified by testing with triple-layer carbonless copy paper. Under 0.6 MPa air pressure and 200 °C sealing temperature, the sealing results remain uniform and consistent.

specifications

| Product Name | Automatic Quad Station Heat Sealing Machine |

| Voltage | AC 220V/50Hz, or 110V/60Hz |

| Net Weight | 800 kg |

| Product Dimension | 900*900*1500mm (L*W*H) |

| Sealing Length | ≤200 mm |

| Sealing Width | Top seal 3.5mm (soft seal), side seal 6mm, The upper mold limit height is 0.18mm. |

| Sealing Thickness | 0.16-0.3 mm |

| Sealing Temperature | The room temperature ~ 230℃ adjustable (control accuracy of ±3℃) |

| Heating Timer | 0 ~ 99.9 seconds adjustable |

| Rotary Accuracy | ≤ 30 |

| Sealing Parallelism | ± 0.01 mm |

| Productivity | 400-500 pcs/hour (depending on placement proficiency) |