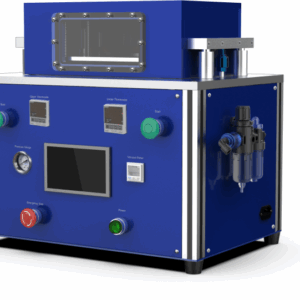

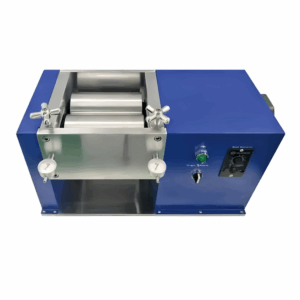

The Plunger Pump Precision Liquid Injection Equipment is a high-accuracy fluid dispensing system designed for controlled, repeatable liquid delivery in industrial, medical, and laboratory applications. Utilizing a plunger pump mechanism, it ensures ultra-precise volumetric dosing (µL to mL range) with minimal pulsation, making it ideal for applications such as adhesives, lubricants, pharmaceuticals, and microfluidic systems.

Features

- The parts in contact with the medium are all made of ceramics.

- Suitable for high-end and micro-precision dosing, filling, addition, injection, spraying, and marking of liquid media. Featuring a valveless design, it ensures extremely stable flow with a flow accuracy of ±0.3%.

- The pump core and pump sleeve are manufactured with a combination of nanotechnology and gel casting molding technology, resulting in a uniform microstructure and extremely high density. The components are precisely matched, utilizing advanced ceramic technology that achieves self-sealing and self-lubricating properties without the need for additional seals or lubricants.

- The pump sleeve and its components are resistant to acids, alkalis, and can adapt to liquid metering in harsh environments.

- The design features a positive displacement piston structure with reciprocating rotational operation. The flow rate can be adjusted by modifying the stroke length or rotational cycle.

- The liquid injection is no waste, no bubbles, no leakage, no dribbling, and no clogging.

- The system has high-performance features. It offers multiple capacity and speed options, and can instantly reverse the liquid transfer direction.

- Without dynamic sealing parts and vulnerable parts, it is easy to maintain.

- Capable of metering and injecting liquid according to preset parameters. It automatically stops metering when the specified liquid volume is reached.

- Equipped with a standard communication interface, it can be used independently or conveniently communicate with PLC or industrial control computers.

- Operators can calculate the total liquid volume based on actual production needs using the formula: Q_total (Total Liquid Volume) = Q_stroke (Stroke Volume) * N_stroke (Number of Strokes).

- Features configurable functional modes such as forward pumping, reverse pumping, reverse pumping volume, delayed metering, standby cleaning, and production counting.

- The machine is compact and aesthetically designed, flexible to use, easy to operate, stable in performance, safe, and reliable.

Specifications

| Product Name | Plunger Pump Precision Liquid Injection Equipment |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Pump Core Material | ZrO2、Al2O3 |

| Pump Core Performance | Corrosion resistance, high temperature resistance, wear resistance, high hardness, low friction coefficient, long service durability |

| Pump Core Matching Accuracy | 2 μm |

| Driving Method | Servo/stepper motor driven |

| Speed Range | 1 – 1200 rpm (Reversible) |

| Speed Control Method | Pulse |

| Single-stroke Capacity Range | 0 μL – 10,000 μL Max. 10,000 / 1 stroke |

| Calculation Method of Capacity | Total flow rate (Q_total) = Stroke flow rate (Q_stroke) × Number of strokes (N_strokes) |

| Metrological Accuracy | ± 0.5% |

| Applicable Temperature of Medium | The temperature of the medium liquid is ≤ 250 °C. |

| Liquid Guide Tube | Inlet: inner Ø6, outer Ø8; outlet: inner Ø6, outer Ø8 |

| Liquid Outlet Needle | Ø2.5 /Ø 4.0 /Ø6.0 (Customizable) |

| Metering Pump Dimension | 201mm*125mm*147mm(L*W*H) |

| Controller Dimensions | 295mm*215mm*157mm(L*W*H) |

| Net Weight | 27 Kg |

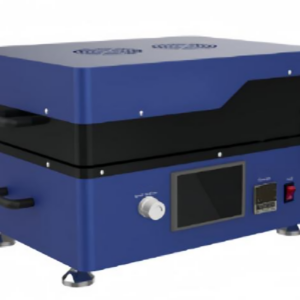

| Required Working Environment | Temperature: 0 ~ 40°C Relative humidity: < 80% |