The Pouch Cell Pre-sealing Machine evacuates the air inside the battery core or battery pack using vacuum extraction to meet specific vacuum degree requirements, improving the battery’s sealing and safety, and preparing for the subsequent packaging steps.

Features

- The sealing heads are made of high-conductivity copper, providing excellent heat transfer performance, reducing power consumption, and improving working efficiency—more energy-efficient than similar products.

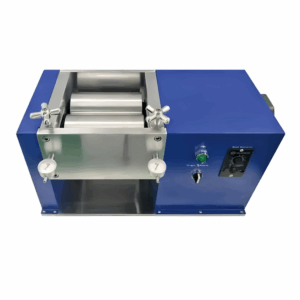

- The pressure of the upper and lower sealing heads can be adjusted via pressure-regulating valves to meet different process requirements.

- The upper and lower sealing heads are driven by air cylinders and guided by dual linear bearings, ensuring smooth vertical movement and precise alignment for high sealing parallelism.

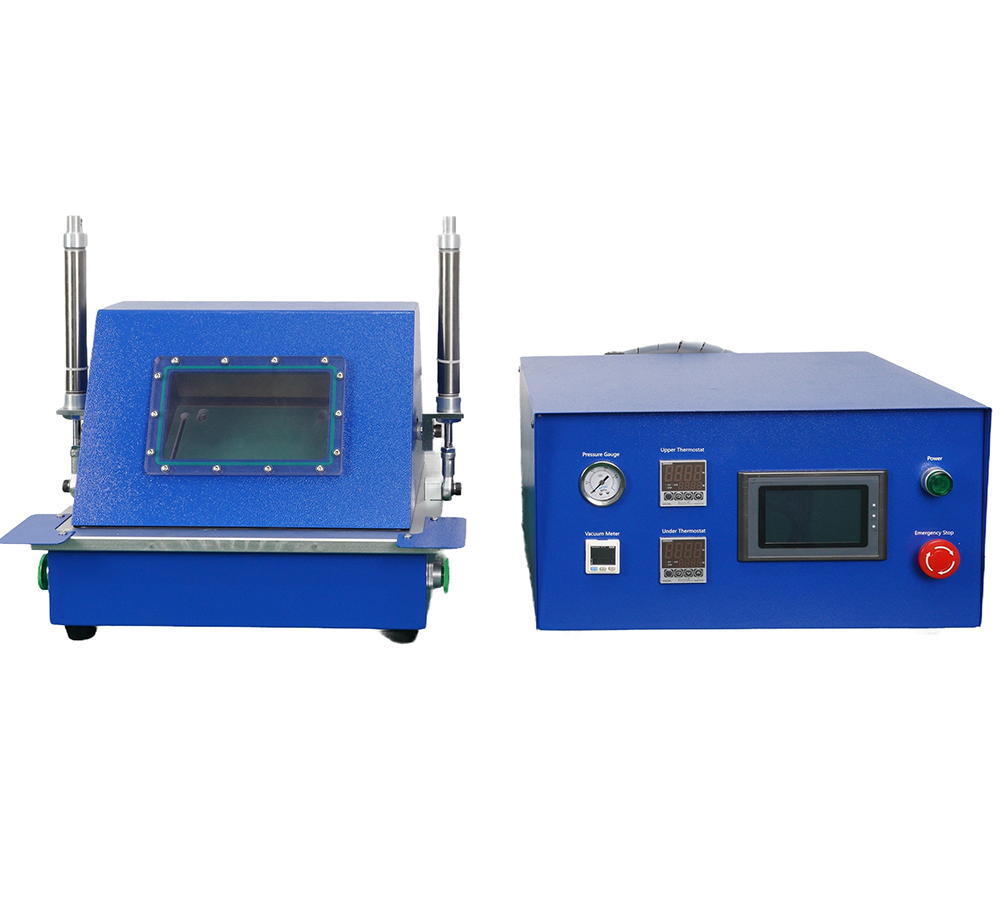

- Equipped with a transparent observation window for monitoring the process inside the chamber during operation.

- The chamber cover is driven by an air cylinder and guided by a rotary sleeve, ensuring smooth movement and accurate positioning to guarantee sealing integrity.

- Suitable for various battery sizes, with simple and convenient adjustment.

- The machine adopts a split design between the main unit and control box, allowing it to operate both inside a glove box or on a production line.

- Simple operation, compact structure, lightweight design, and attractive appearance.

Specifications

| Product Name | Pouch Cell Pre-sealing Machine After Electrolyte Filling |

| Sealing Head Length | LT-YF200: 200mm LT-YF300: 300mm |

| Sealing Width | 5 mm |

| Sealing Head Temperature | room temperature ~ 250°C |

| Temperature Control Accuracy | ± 2 ℃ |

| Heat Sealing Time | 0 ~ 99 seconds |

| Vacuum Degree | Max – 95Kpa (adjustable) |

| Heat Sealing Pressure | 0 – 7 kg/cm², adjustable |

| The parallel gap when the upper and lower heads are joined | ≤0.02 mm |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Power Consumption | Equipped with a 500 W heating tube; power consumption during heating is approximately 1 kW |

| Required Air Source | 0.5 – 0.8 MPa |

| Product Dimension | Working Part: LT-YF200: 470mm*485mm*435mm(L*W*H) LT-YF300: 570mm*485mm*435mm(L*W*H) |

| Control Box: LT-YF200: 420mm*325mm”225mm(L*W*H) LT-YF300: 520mm*325mm”225mm(L*W*H) | |

| Net Weight | About 50 Kg |