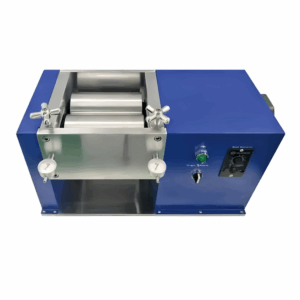

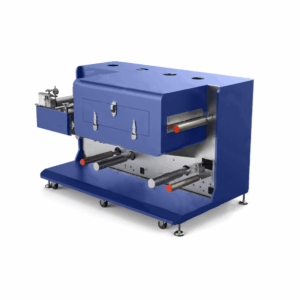

This advanced Thermal Press and Shaping Machine for Pouch Cells with Short-Circuit Test Function integrates thermal pressing, edge shaping, and in-line short-circuit detection for lithium-ion pouch cell manufacturing, ensuring structural integrity and electrical safety in a single automated process. The Thermal Press and Shaping Machine with Short-Circuit Test Function is primarily used for the hot flat pressing and shaping of battery cells. Through pressurization and heating, the battery cells are shaped to achieve a consistent thickness, reduce their elasticity, lower the short-circuit rate during cell assembly, and ensure the consistency of the finished battery cell thickness.

Features

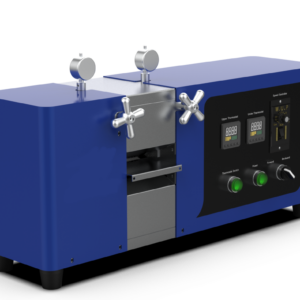

- The temperature of the workbench surface can be adjusted and set through the buttons on the temperature controller panel. Both the current parameter and the set parameter can be displayed on the LED screen, which is intuitive, clear, highly precise in temperature control, and easy to operate.

- The pressure of the upper and lower workbench surfaces can be adjusted via the pressure regulating valve to meet different process parameter requirements.

- This machine features a single-station structure, characterized by high parallelism between the upper and lower workbench panels, as well as a stable design.

- The workbench surface is made of high-quality materials, ensuring good heat transfer, saving power consumption, and improving work efficiency.

- Equipped with a light curtain protection device for safe use.

- The machine features both manual and automatic testing functions.

- It can identify the micro-circuit condition of batteries through precise insulation resistance testing, thereby assessing the safety performance of the batteries.

- During operation, it can run automatically via electrical control, while manual functionality is available for debugging purposes.

Specifications

| Product Name | Thermal Press and Shaping Machine with Short-Circuit Test Function |

| Working Pressure | 0 ~ 900kg, ±3kg |

| Working Distance | 0-80mm |

| Battery Size | Max 200mm*200mm*70mm(L*W*H) |

| Temperature Control Accuracy | ±4℃ |

| Resistance Range | Max 199 MΩ |

| Measurable Leakage Current | Max 50 μA |

| Input DC Voltage for Testing | 0 ~ 500V |

| Test Timer | 0 ~ 99s |

| Heating Temperature | room temperature ~ 130°C |

| Net Weight | About 180 Kg |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 2KW |

| Required Air Pressure | 0.5Mpa~0.8Mpa |

| Product Dimension | 350mm*320mm*550mm(L*W*H) |