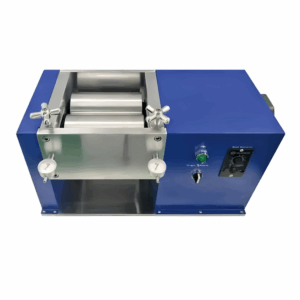

The Electrode Slitting Machine is a precision cutting system to convert large rolls of coated electrode material (anode/cathode) into narrower strips for pouch and cylindrical cell assembly. The machine ensures clean, burr-free edges to prevent internal short circuits and improve battery performance.

Features

- Adjustable guiding device for sheet positioning.

- An electric rotary cutting and slitting method was adopted.

- The meshing amount is adjustable.

- The top and bottom blades operate at the same speed with synchronous transmission.

- An acrylic glass protection device is equipped at the rotary blade for safe operation.

- Open-type rotary blade fixing method, facilitating blade replacement.

- High slitting precision and reliable operation.

- The die-cut product has minimal burrs, no dusting, no indentation, or other appearance defects.

- Simple operation, safe and reliable, aesthetically pleasing appearance, and compact size.

Specifications

| Product Name | Electrode Slitting Machine |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Cutting Blade Type | Top and bottom set of round blades |

| Cutting Blade Width | LT-FT300: 20~300mm LT-FT350: 20~350mm |

| Cutting Thickness | 80 – 300 μm |

| Burrs Condition | ≤25μm |

| Cutting Blade Diameter | 100mm |

| Cutting Speed | 1 – 4 m/min, adjustable |

| Rated Power | 200W |

| Dimension | LT-FT300: 850*920*400mm(L*W*H) LT-FT350: 950*920*400mm(L*W*H) |

| Net Weight | 100KG |