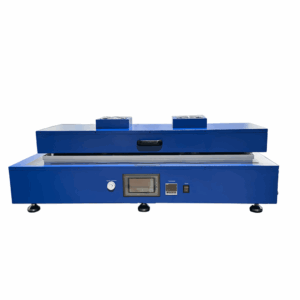

The Automatic Electrode Die-Cutting Machine cuts electrode-coated foils (e.g., graphite, NMC, LFP) into precise shapes (slit, tab, or custom geometries) with micron-level accuracy, ensuring optimal performance in energy storage devices. Meanwhile, the Automatic Electrode Die-Cutting Machine is a high-precision industrial equipment designed for the mass production of electrode sheets used in batteries (Li-ion, solid-state), supercapacitors, and fuel cells. It enables efficient cutting of anode/cathode-coated foils (graphite, NMC, LFP) into precise shapes with micron-level accuracy, ensuring optimal performance in energy storage devices.

Features

- The precise fixed-length feeding is carried out by a manipulator which controlled by a motor, and precise correction is performed during the feeding process to ensure that the electrode sheet can be accurately fed to the designated position.

- The precise fixed-length feeding part has a memory function. It can automatically compensate for materials during the feeding process to eliminate errors, thereby ensuring the accuracy of feeding.

- The base of the cutting machine is made by integrated assembly, and it is equipped with a four-rod linkage driving mechanism. This makes the punching pressure more uniform and stable, the cutting repositioning more accurate, and the edges of the punched electrode sheet smoother. It effectively reduces the replacement frequency of the PET conveyor belt and prolongs the durability of the blade.

- The blade is equipped with an advanced automatic locking device. The locking force is uniform, the operation is simple, and the loading and unloading are convenient. This automatic locking device can rotate and swing within a certain angle when locked. If the blade is not installed correctly, it can be adjusted within a certain range.

- An electrostatic elimination device is equipped on the PET film to prevent dust.

- When the blade is cutting, a small amount of dust will remain on the PET film, which using a brush for cleaning.

Specifications

| Product Name | Automatic Electrode Die-Cutting Machine |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 6.5KW |

| Cutting Speed | 15 – 30 Pieces per minute |

| Feeding Width | Max 520mm |

| Cutting Size | Max 520mm*400mm Min 59mm*64mm |

| Cutting Thickness | 0.06mm ~ 0.25mm |

| Cutting Precision | ±0.2mm |

| Length of the burr in the Z direction. | ≤±0.01mm |

| Length of the burr in the X direction. | ≤±0.02mm |

| Blade Durability | ≥ 30,000 times |

| Electrode Material Convey Method | PET conveyor enables cyclic material feeding |

| Requested Air Pressure | 0.5~0.7Mpa |

| Product Dimension | 4600mm*2500mm*1800mm(L*W*H) |

| Net Weight | 4600Kg |