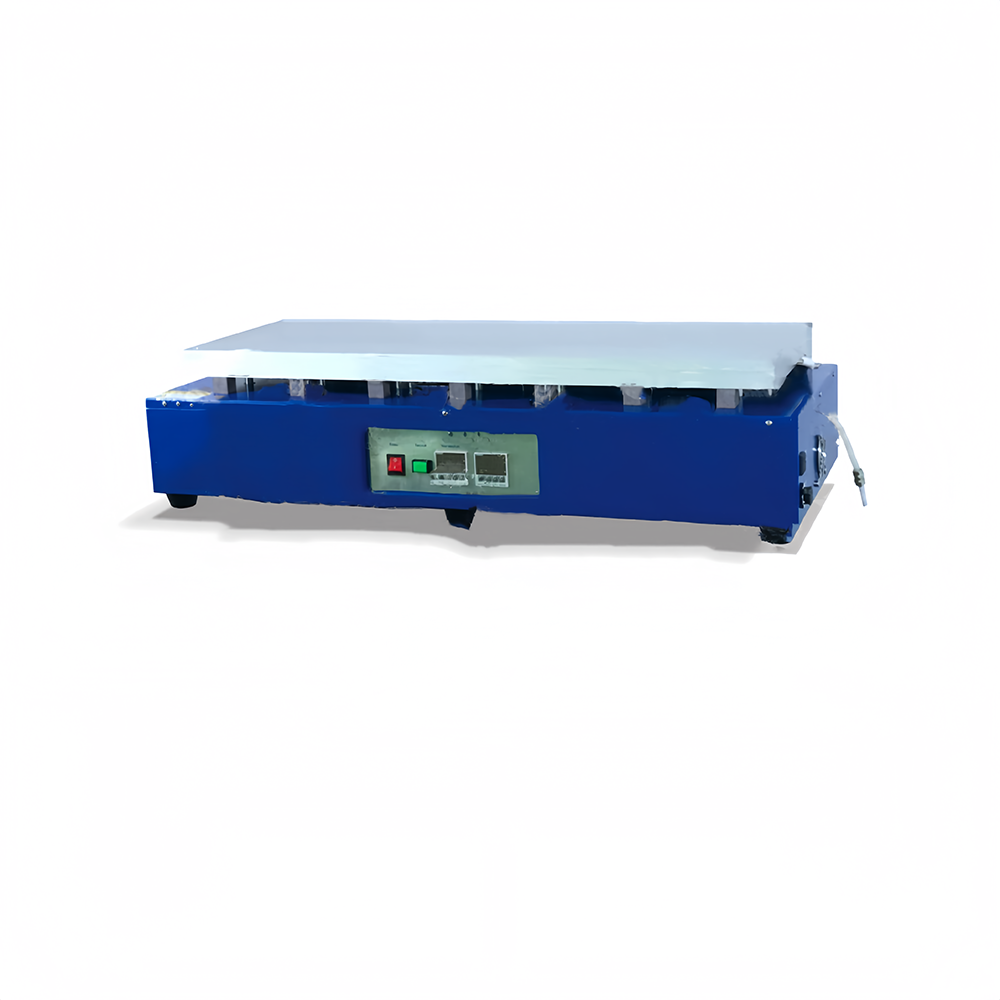

A coating machine with a heated plate is designed to apply a uniform electrode slurry (anode or cathode) onto metal foils (Cu/Al) while controlling the drying degree through precision thermal management. This integrated heating system improves coating quality, reduces defects, and enhances production efficiency.

Features

- Adopt a bottom heating and drying system.

- Coating speed is adjustable within the range of 0 to 100 mm/s.

- Drying system with digital temperature display control.

- Stroke adjustable between 10 to 250 mm via limit switches; vacuum aluminum disc allows for quick placement or removal of substrates.

- Equipped with an adjustable coater.

Specifications

| Product Name | Coating Machine with a Heated Plate |

| Maximum Stroke | 250mm |

| Vacuum Plate Material | aluminum flat plate |

| Vacuum Plate Size | 365mm*200mm*30mm (L*W*H) |

| Coating Thickness | 0.01 ~ 3.5 mm |

| Coating Speed | 0 ~ 100 mm/s |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Net Weight | 50 KG |

| Product Dimensions | 500mm*310mm*260mm (L*W*H) |