A Precision Electrolyte Filling Machine is a critical system in lithium battery production that accurately injects liquid electrolyte into pouch, prismatic, or cylindrical cells with micron-level control. This automated process ensures proper wetting of electrodes while minimizing waste and contamination risks.

Features

- Due to the highly corrosive nature and tendency to crystallize into solids of supercapacitor electrolytes, valves and pipelines are prone to blockage, which severely hinders the normal injection process of electrolytes. To address the extremely harsh operating conditions involving strong corrosion and crystallization, our company boasts extensive hands-on experience in electrolyte injection for multiple supercapacitor clients. We have continuously optimized the injection structure, valve components, and pipeline layout, completely resolving the challenges of corrosion and crystallization.

- A multi-stage filtration system and specialized adsorption materials ensure unobstructed valves and pipelines while protecting the vacuum pump from corrosion, damage, and clogging of the pump impeller.

- During the injection process, exposure to electrolytes inside the glove box is minimized, significantly reducing the volatility and corrosion of other glove box components.

- Equipped with a DMC cleaning function, primarily used for monthly or quarterly maintenance to keep the pipelines clean.

- Utilizes specially designed dual-path pneumatic valves that prevent clogging, with internal components made of SUS316 and PTFE materials for superior corrosion resistance.

- Delivers exceptional metering precision and repeatability, with an electrolyte injection accuracy of ±1%.

- Applies a vacuum-first, then injection process, followed by alternating vacuum and pressure during the static settling phase—ensuring high efficiency, precision, and reliable operation.

- Key parameters such as vacuum time, high/low vacuum levels, injection volume, static settling time, pressurization pressure time, and depressurization time are all adjustable and programmable.

- Features an anti-corrosion, long-durability design, with critical components made of high-quality elements.

- The connectors of injection tanks are made of stainless steel, hoses are constructed from corrosion-resistant PE material, and the main part is crafted from aluminum alloy—ensuring overall corrosion resistance.

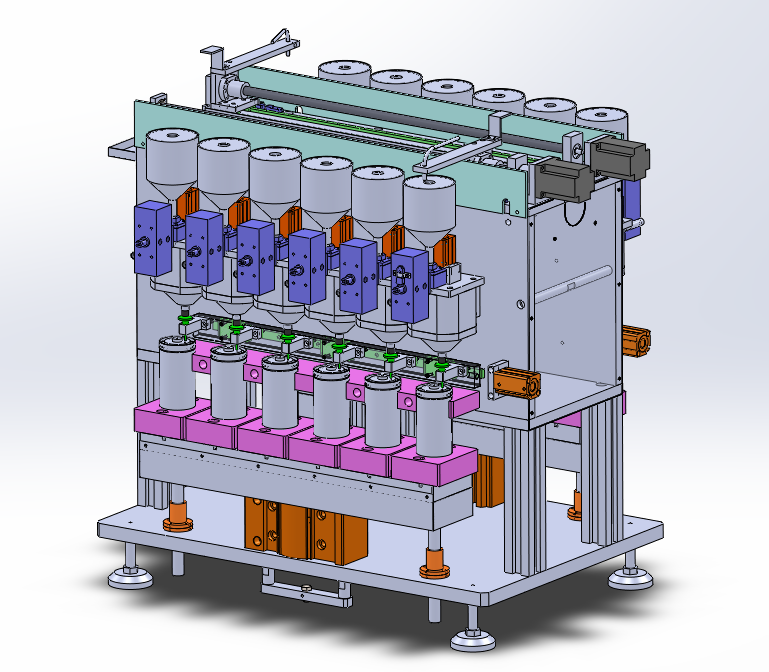

- Tooling fixtures are designed for quick and easy disassembly to adapt to products of varying heights.

SPECIFICATIONS

| Product Name | Precision Electrolyte Filling Machine |

| Applicable Products | Supercapacitor cells with a diameter of 60 mm and a height range of 50–138 mm |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 1.5KW |

| Filling Volume | 0 ~ 250ml Adjustable |

| Vacuum Range | During electrolyte injection, the vacuum pressure is maintained at ≤ –98 kPa |

| Required Nitrogen Gas | ≥0.4MPa |

| Product Dimension | 900mm*700mm*760mm(L*W*H) |

| Filling Accuracy | ±1% |

| Productivity | One injection cycle: 12 minutes 12 filling stations, capable of injecting 12 cells per cycle Each station operates independently, allowing flexible selection and non-interfering operation |

| Product Material | The filling tank connectors are made of stainless steel The hoses are corrosion-resistant PE hoses The machine body is constructed from aluminum alloy, ensuring overall corrosion resistance |