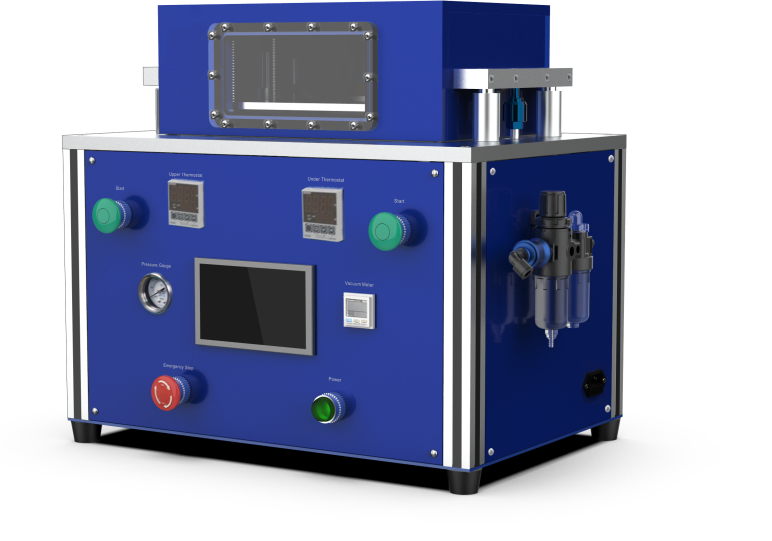

The vacuum sealing machine is used to degas and reseal a pouch cell after electrolyte injection and cell formation. It ensures air-free encapsulation of electrodes and electrolytes to prevent the exposure of the cell materials and electrolyte leakage. This machine automatically vacuums and seals the pouch after piercing the airbag.

It has a compact design and fits most stainless steel gloveboxes.

Features

- The sealing head is made of copper with excellent heat transfer, resulting in improved efficiency.

- The sealing pressure can be adjusted through a regulator to meet different process requirements.

- The upper and bottom heads are driven by a cylinder and guided by two linear guide sleeves, ensuring flexible movement and accurate guidance to meet the parallelism requirements after product edge sealing.

- Automatic pierce.

- The chamber lid is driven by a cylinder and guided by a linear guide sleeve, ensuring flexible movement and accurate sealing requirements.

- Suitable for sealing pouch cells of different sizes.

- Compact design, easy operation, lightweight.

Specifications

| Product Name | Vacuum Sealing Machine |

| Sealing Temperature | room temperature ~ 250°C (adjustable) |

| Sealing Temperature Control Accuracy | ±1.5℃ |

| Sealing Pressure | Adjustable from 0 to 7 Kg/cm² |

| Heating Timer | Adjustable from 0 to 99 seconds |

| Operating Speed | ≥ 180 cycles/hour |

| Sealing Width | 5mm |

| Maximum Edge Sealing Size | LT-BFZ200: 200mm LT-BFZ300: 300mm LT-BFZ400: 400mm |

| Vacuum Level | Max -95Kpa, adjustable |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Net Weight | 100 KG |

| Rated Power | 900W |

| Input Air Pressure | 0.5-0.7MPa |

| Dimension | LT-BFZ200: 500mm*500mm*700mm (L*W*H) LT-BFZ300: 600mm*600mm*700mm (L*W*H) LT-BFZ400: 700mm*700mm*700mm (L*W*H) |