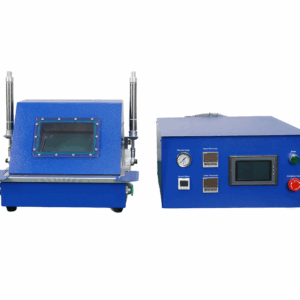

The Vacuum Slurry Mixer is a high-efficiency industrial mixing system designed for homogeneous blending of powders, liquids, and viscous slurries under vacuum conditions. It eliminates air bubbles, prevents oxidation, and ensures uniform dispersion—critical for battery electrode pastes, ceramic slurries, pharmaceuticals, and advanced coatings. A Vacuum Slurry Mixer is suitable for mixing positive and negative electrode slurry during battery experiments, as well as for mixing powdered materials and various ceramics. The time, speed, and rotation direction can be set via a programmable controller.

Features

- Utilizing the soft sealing process, which is the industry-leading, it can maintain a pressure of -0.098MPa for over 24 hours.

- Equipped with precision guiding columns for support, the cylinder automatically drives the opening and closing of the bucket, featuring a user-friendly and precise design.

- A double-layer stainless steel container with 1 L, the bucket body is made of high-quality 304 stainless steel, precision-machined on a lathe, and then polished with a high-precision automatic polishing machine to ensure high accuracy.

- The stirring motor adopts gearbox frequency conversion adjustment, allowing for the selection of different speeds and torques according to various processes and viscosities.

- The dual dispersing blades design ensures that materials are thoroughly mixed up, as well as around the sides, achieving rapid and uniform mixing of the slurry.

- The exterior is exquisitely designed with a three-dimensional geometric style, simple and elegant.

- It has a timer function; the time can be set arbitrarily from 0 to 99 seconds.

- Self-terminate when the timer expires and maintain the vacuum state.

Specifications

| Product Name | Vacuum Slurry Mixer |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 0.75W |

| Stirring Speed | 0 ~ 1400 rpm |

| Effective Capacity | 1L (2L can be customized) |

| Opening and Closing Method of the Bucket | The upper cover is lifted by a double-stage vacuum pump |

| Bucket Dimension | 106 mm (inner diameter) × 175 mm (height) |

| Machine Dimension | 800*300*700mm(L*W*H) |

| The Can Lid Contains | Vacuum gauge, vacuum extraction port, etc. |

| Net Weight | about 90 Kg |