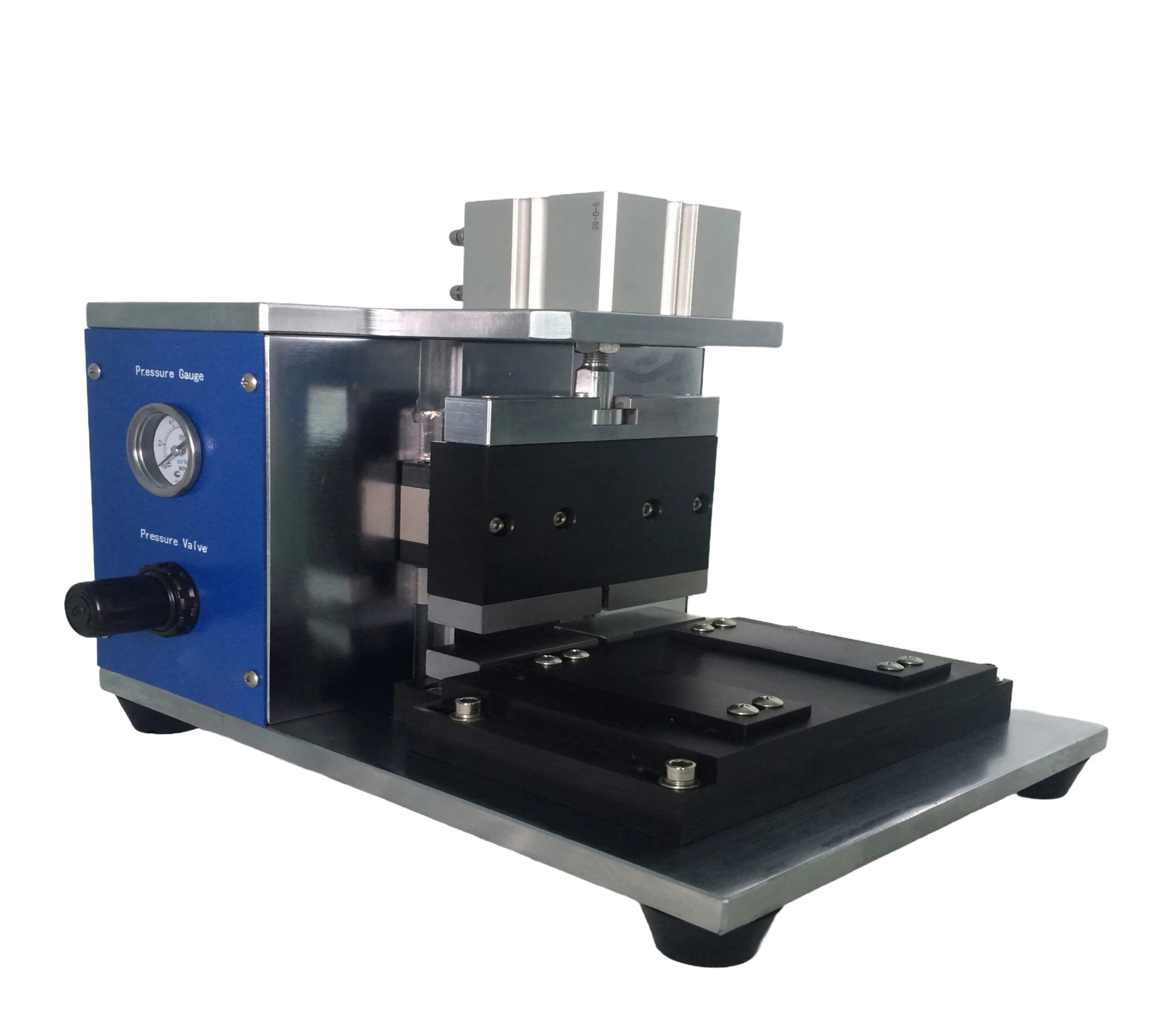

This Current Collector Tab Shaping Machine is responsible for precisely slitting and preparing the current collector tabs (usually made of aluminum for the cathode and copper for the anode) before they are welded. It ensures high-accuracy tab shaping for consistent electrical performance and seamless integration into pouch cell stacks.

Features

- Extremely high guiding accuracy is guaranteed to ensure the flatness of the upper and lower mold plates.

- Easy operation, high efficiency, stable temperature, and good consistency.

- Use fixtures for feeding, and drive the mold with a cylinder to achieve shaping.

- Set up a product positioning tray to facilitate the positioning and placement of the battery cells.

- The machine is attractive, reliable, convenient, and fast.

- The speeds of the upper and lower flattening plates, as well as the shaping time, can be adjusted and set.

SPECIFICATIONS

| Product Name | Corrent Collector Tab Shaping Machine for Pouch Cell Preparation |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Pouch Cell Dimension | within 150mm*150mm(L*W) |

| Hardness of Shaping Mold | ≥ HRC58 |

| Mold Durability | 3 million times/shaping |

| Ironing Temperature | room temperature ~ 250 °C |

| The distance between the top and bottom flattening board | >50mm |

| Shaping Speed | 600 times/hour |

| Compressed Air Source | 0.5Mpa ~ 0.7Mpa |

| Product Dimension | 230mm*200mm*250mm(L*W*H) |

| Net Weight | 27Kg |