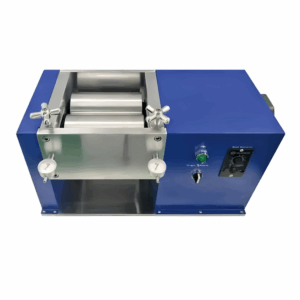

The Electric Rolling Press with a width of 150mm is a useful tool for materials that require precise and efficient processing into thin sheets or films. It consists of two 96 mm diameter rotating rollers that apply pressure to the material being processed. The rollers are powered by an electric motor, which allows for precise control over the pressing force and speed. It’s commonly used in Li-Ion batteries research after coating and drying. The thickness of the rolling is adjustable and easy to use.

SPECIFICATIONS:

| Product Name | Electric Rolling Press with Width 150mm |

| Rolling Thickness | Adjustable 0 – 2 mm |

| Rolling Width | 0 – 150 mm |

| Roller Diameter | Ø 96 mm |

| Roller Surface Hardness | HRC 60-62 |

| Roller Surface Finish (Ra) | above 0.4 |

| Roller Placement | Vertical placement |

| Feeding Speed | Adjustable 0 – 50 mm/s |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 120 W |

| Product Dimensions | 435*245*355 mm (L*W*H) |

| Net Weight | 65 kg |

Reviews

There are no reviews yet.