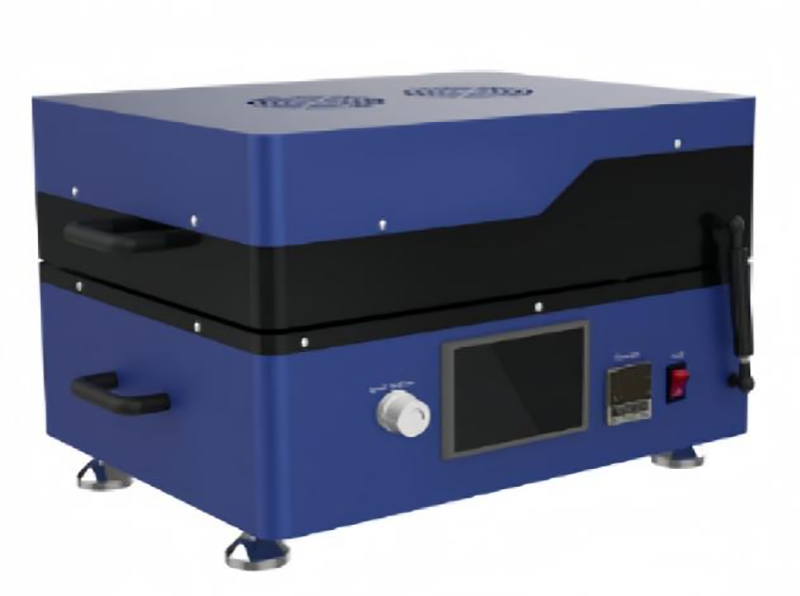

The Compact Film Coating Machine with Vacuum Chuck and Drying Heater for Battery Electrode is widely used in various high-temperature coating research, such as ceramic films, crystal films, battery material films, and special nano-films; it can adapt to the development of science and technology for film formation under high-temperature conditions in the future.

Features

- Using large area uniform heating to ensure high precision and uniform temperature in the cavity.

- Flat coating, motor-driven scraper coating, stable and adjustable coating speed.

- The coating film speed is adjustable. The vacuum aluminum pan can quickly place or remove copper foil, aluminum foil, etc., built-in vacuum pump or connected to an external vacuum source, and the substrate is adsorbed without deformation.

- Standard film dispenser, high coating precision, coating, Adjustable cloth thickness.

- Can be used in the glove box, easy to operate and small in size, which can save space.

- PLC Touch screen control for easy parameter setting.

Specifications

| Product Name | Compact Film Coating Machine with Vacuum Chuck and Drying Heater |

| Coating Stroke | Max 250mm |

| Coating Speed | 0~100mm/s |

| Vacuum Plate | Equipped with vacuum aluminum plate |

| Dimension of the Vacuum Plate | 365mm*200mm*30mm (L*W*H) |

| Coating Blade Range | 0.01 – 3.5 mm |

| Heating & Drying System | Room temperature to 250 °C, digital temperature controller, accuracy ±1 °C |

| Voltage | AC220V/50Hz, or AC110V/60Hz |

| Rated Power | 2KW |

| Net Weight | 65KG |

| Product Dimension | 500mm*310mm*330mm (L*W*H) |